Hougaard & Koefoed as Company Center

A SUCCESSFUL SHEET METAL COMPANY – SINCE 1948

Hougaard & Koefoed is a company which successfully specializes in sheet metal fabrication and consultancy services, primarily within the defence, aerospace and medical industries. Since our establishment in 1948, we have gained a steadily-growing share of our market. Our production area exceeds 4000m2.

THE MOST SKILFUL EMPLOYEES & SUPPLIERS

With a team consisting of the most skilful, dedicated employees and the most reliable suppliers in the business, we are capable of servicing clients with high demands for quality and guaranteed delivery.

Our quality management system provides an exceptionally important foundation for our services. It is our clearly defined goal to be able to guarantee and deliver precise and faultless products. We are therefore very proud of the fact that we have gained international recognition for our work – first in 1993, when we received an ISO 9001 certificate and again in 2009 when, as one of the first companies in our line of business, we qualified for the new standard ISO 9001:2008.

Our next goal is to achieve an AS9100C certificate for defence industry production. This certificate will result in further improvements to the security, traceability and documentation of our processes and we expect to achieve AS9100C certification by the end of 2010.

EFFICIENT QUALITY MANAGEMENT

Our quality management system works efficiently due to several factors. It is one thing that we have years of experience and insight and are skilful at our craft. It is another that the quality requirements for each product are documented in our ERP system, either by specific customer instructions or in the form of our own quality standards. Our ERP system ensures that a quality plan is worked out for every order in our production, so every demand is met according to customer specifications.

An important part of our quality management is the internal exchange of experience between departments. All of our employees co-operate as links in a process-oriented system with total focus on structure and documentation – and are thus fully involved in developing and achieving both internal and external objectives. Our entire company contributes to the quality development that is our Quality Department’s primary responsibility.

QUALITY DEPARTMENT

We have consciously chosen to place the Quality Department in a central area – at the very heart of our production. It enables a perfect overview of day-to-day workflow and provides good motivation to our employees, who are constantly inspired to hone their expertise and focus on keeping the quality of our work at an impeccably high level.

The Quality Team use digital 3D measuring, which ensures exact measurement in all our work and in our measurement reports e.g. FAI (First Article Inspection). Our Quality Department is responsible for ensuring that all conditions for documentation and products are fulfilled before an order is shipped, including a Certificate of Conformance, if required. We are constantly monitoring our quality performance and one of our objectives is less than 1% returned goods. In 2009 the outcome was 0.56%.

COMMUNICATIONS AND CUSTOMER SERVICE

Good communication between all parties is an absolute necessity for success, internally as well as externally. Hougaard & Koefoed has a large team of well-educated, highly-qualified co-workers who know the importance of careful handling of quotations and orders without misunderstandings or contingencies. All customer services personnel are specially trained and have practical experience obtained in either the Production or Quality Department. To facilitate communication, a contact person with ongoing insight into the whole process is allocated to each customer. We handle all customer enquiries confidentially.

ORDER MANAGEMENT

Hougaard & Koefoed uses a sophisticated ERP system (Microsoft Dynamics AX) to control every stage of the order process – from purchasing with certificates to the provision of special transportation. Quotations are treated as open purchase orders. Prices are specified for each individual process – materials, coating, etc and this open calculation gives the opportunity to discuss and optimise each part of the total quotation. When ordering, the quotation can be swiftly transformed into a purchase order, leading to faster production and delivery.

DELIVERY GUARANTEE

We pride ourselves on fulfilling our contracts on time. In 2009, 93% of all orders were delivered on time – that is, on the precise day that the customer wished to receive the delivery. In 2010 we aim to improve our delivery guarantee even further, supported and enhanced by our ERP system and through constant supervision and evaluation.

BROAD KNOWLEDGE AND EXPERTISE

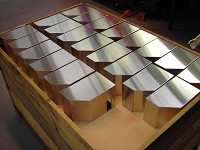

Hougaard & Koefoed’s extensive experience, knowledge and expertise enables us to deliver products in sheet metal fabrication to a wide range of customers in dentistry, medical technology, broadcast, electronic equipment, security and payment systems, also unique products specially created for the defence industry. In addition, we deliver complex products with great accuracy – as prototypes and in small and medium-sized production runs.

PARTNERING

Hougaard & Koefoed are experiencing a growing interest in deliveries of complete products containing different types of competences i.e. design and construction, milling and turning, electronic components, SMD, overlays and membranekeyboards. We are able to bond all these competences together in an effective project-solution.

HOUGAARD & KOEFOED – A STABLE SUPPLIER

It is essential to choose suppliers with great care. Regardless of qualifications, size or branding, a supplier without a strong financial foundation may soon turn out to be a weak link and a costly mistake.

Hougaard & Koefoed is a well-managed and financially secure company. We have the financial strength to ensure stability and close cooperation for our clients, now and in the future.

FACILITIES, CAPABILITIES AND OPTIONS

Precision sheet metal fabrication and assembly:

Design and construction

Manufacture - both small and medium-scale production:

- CNC punching

- Laser cutting

- Bending

- Welding

- Grinding and finishing treatment

- Fasteners, inserts, rivets, etc.

Surface treatment:

- Galvanic surfaces

- Wet and powder finishing

- Serigraphy, silk-screening, etc.

Assembly:

- Mechanical and electro-mechanical parts

- ESD protected

- Wires, wiring and riggings

Logistics and data processing:

- Exchange of production plans and forecasts

- Handling of drawings and models in popular file formats

(radar picture: courtesy from TERMA A/S)

Latest Company News / Press Releases from Hougaard & Koefoed as

- PARTNERING AND D-M-G (Thu 24 Jun 2010)

Products & Services

- Consultancy Services (Aerospace)

- Design, Construction and Engineering Services (Aviation)

- Engineering (Space)

- Engineering (Defence)

- Engineering (Aerospace)

- Manufacturing, Engineering and Test Equipment (Defence)

- Mechatronics (Aerospace)

- Metal Services (Aerospace)

- Research and Development (Aerospace)

- Research and Development (Aviation)

Last update by Per Funch, Mon 2 Aug 2010