Universal Synaptics Corp Company Center

1801 W. 21st St.

84401 - Ogden - Utah

United States

801-731-8508

Intermittent Fault Detection & Isolation System (IFDIS)

Ncompass / IFD 4000 (flight line)

Ncompass / IFD 4000 (portable)

Universal Synaptics Corp.

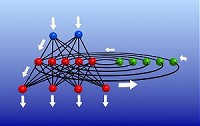

Neural network monitors all lines all the time - no scanning or sampling

Solve your No Fault Found (NFF) problems today!

LRU intermittent fault detection and isolation

Wire harness intermittent fault isolation and detection

Universal Synaptics Corp.

Improve weapon system and war fighter availability and mission readiness

The maintenance of aircraft electronic Line Replaceable Units (LRUs) pose an ever increasing challenge. Much of the challenge is related to intermittent faults which occur because of aging wiring and connections. These intermittent problems manifest themselves as “Bad Actor” LRUs or as repair shop No Fault Found (NFF) and Cannot Duplicate (CND) test results. Universal Synaptics has a proven shop maintenance tool which would augment traditional testing methods by providing an Intermittent Fault Detection and Isolation System (IFDIS) which can be used to identify and isolate intermittent faults, as well as any other wiring problems in complex LRU chassis’ and aircraft wiring.

Intermittent faults are a growing problem in electronic equipment. As integrated circuits (ICs) and other electronic discrete parts become increasingly capable and reliable, an ever growing portion of the electronic equipment maintenance problems encountered are not component failure, but rather interconnectivity problems between the electronic piece parts.

The intermittent can be caused by a loose or corroded wire wrap, a cracked solder joint, a corroded connector contact, a loose crimp connection, a hairline crack in a printed circuit trace, or via’s, or a number of other phenomena, all very common in electronic equipment. Many times the intermittent open circuit will manifest itself during an initial troubleshooting test, such as in the electronic back shop of a commercial repair facility or military flying wing, but by the time the equipment item has been transported to a commercial or military depot for repair the intermittent circuit is no longer open. This results in NFF. Some LRUs now test NFF over 50% of the time when inducted into the repair shop.

Many of the “failed” WRAs end up testing NFF, having no parts replaced and no other repair work performed at the depot. These boxes are turned right around and returned to the field or flight line as fully operable boxes, because the depot is unable to detect a problem. Our research indicates that intermittent / NFF is a multi-billion dollar a year problem for our military.

Not only do these expended funds accomplish nothing useful, but the WRAs experience the needless “wear and tear” of being shipped from the field or flight line to the depot and back again. A substantial share of these inconsistent test results and this NFF activity is attributed to intermittent circuits.

A common rule-of-thumb for older aircraft is that 40% to 60% of all pilot-reported aircraft system malfunctions which occur in the air go undetected during follow-on ground testing. These equipment items, with documented in-flight failures, operate properly, or NFF, during post-flight testing, and thus the problems remain as undetected, unrepaired latent defects. The unit is placed back into service, hazarding the aircraft, crew and passengers, repeatedly wasting maintenance and operational resources and adversely affecting operational sortie capability. NFF resulting from age-induced intermittency is now one of the biggest aircraft maintenance cost drivers for the United States Government.

Universal Synaptics Intermittent Fault Detection and Isolation System (IFDIS) fills a serious test void. The system employs a thermal chamber with an integral shake table to induce light simultaneous thermal and vibration stress to the chassis while it is being interrogated by the Intermittent Fault Detector (IFD) which monitors all circuit paths concurrently and continuously, detecting any intermittent as short as 50 nanoseconds. The temperature and vibration parameters are adjusted to levels appropriate for detecting intermittent faults in the particular item under test and strict adherence to the tolerances set by the Original Equipment Manufacturer (OEM) are followed. The IFDIS provides a repeatable and vigorous test scenario, leading to high confidence that any circuit intermittencies are detected and isolated, enabling subsequent surgical repair. Repairing an intermittent circuit is not difficult; it is detecting and isolating the intermittency that presents the challenge.

We just completed the F-16 AN/APG-68 Radar System Modular Low Power Radio Frequency (MLPRF) joint testing project with Air Force.

The F-16 MLPRF chassis’ is the box with the highest NFF cost of all F-16 avionic boxes. The boxes that have malfunctioned and/or tested bad in the field usually end up testing NFF at the depot and are subsequently returned to service as fully operational boxes.

More than $13,000,000.00 in maintenance costs is incurred annually by the U.S. Air Force for just that portion of the F-16 electronic boxes that test NFF at the depot.

As of May 2010 - 146 MLPRF chassis have been tested by the Intermittent Fault Detection and Isolation System (IFDIS).

Of the 146 MLPRF chassis tested –

- 109 were considered “un-repairable” - completely out of service.

- 33 had been in the shop for over one year

- 9 had been in the shop for over three years

- 100 chassis or 70% had one or more intermittent circuits

- 33 had “opens”, 9 had “shorts”, and 4 were wired incorrectly

100% of the IFDIS tested MLPRF chassis’ have been returned to service.

The cost of a replacement MLPRF chassis is $307,000.00ea x 109 chassis recovered = $33,463,000.00 ROI and counting! We briefed folks at the Pentagon Reduction in Total Ownership Cost (RTOC) Program Office a few weeks ago and we were informed that the IFDIS RTOC is the highest ROI project in the history of the program and counting.

Also, of the MLPRF chassis’ IFDIS tested the average Mean Time Between Failure (MTBF) was 301 hours – MTBF after IFDIS testing on an MLPRF chassis is currently 656 hours and climbing. Or an additional cost savings to the Air Force of $1,100,000.00 annually.

The IFDIS “continuity” and “short” tests diagnosed most of the problems in minutes. In addition to diagnosing existing intermittent / NFF problems, the IFDIS also caught developing problems resulting in failure avoidance opening the door for the IFDIS to function as a preventative maintenance tool, and final assessment test station before product is sent to the field or flight line.

There is a testing-void in that legacy test equipment simply cannot see intermittence. After testing with the IFDIS for these long overlooked defects, the actual repair and refurbishment of these boxes was minimal contributing to the massive ROI associated with the IFDIS. Nearly all of the “un-repairable” NFF boxes had only 2 – 3 problems keeping them from being repaired and returned to inventory, the IFDIS indentified these defects within minutes.

The IFDIS approach is simple, highly cost effective and 100% successful in fixing this aging related testing void. The IFDIS approach is wholly generic and can likely be used to test every box and wiring system in the DOD inventory.

Contact Universal Synaptics to solve your NFF problems today!

Products & Services

- Avionics Systems, Instruments and Components (Aerospace)

- Consultancy Services (Space)

- Electrical Components (Aerospace)

- Electronic Components (Aerospace)

- Maintenance, Repair and Overhaul (Aerospace)

- Manufacturing, Engineering and Test Equipment (Defence)

- Research and Development (Space)

- Research and Development (Aerospace)

- Test / Inspection Equipment (Defence)

- Test / Inspection Equipment (Aviation)

Last update by Ken Anderson , Fri 21 May 2010