Breumaf BV Company Center

Spinelstraat 40 - 7554 TW Hengelo (Ov)

P.O.B. 362 - 7550 AJ Hengelo (Ov)

Netherlands

Solids, wire frames and surfaces in STEPS and IGES

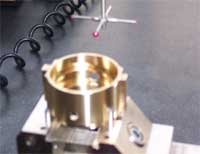

Robot made products

Robot made products

Mitutoyo Crysta Apex C776

Competences

- Producing complex high-precision components using the most modern production methods (3D) programming and machinery.

- A strong focus on CNC-machining, where early participation during design and construction is essential.

- Breumaf applies a high level of flexibility, in order to satisfy a wide range ofrequirements requested by our customers.

- Continuous investment in state-of-the art machinery in response to ever more stringent product and quality requirements.

QA; ISO 9001/2000 and AQAP 2110

Tool Manufacturing

- Moulds:

- Aluminium moulds for the automotive industry

- Steel injection moulds for the packaging industry

- Aluminium moulds for the bottling industry - Dies:

- Follow dies, cutting dies

- Forming dies

- Deep drawing dies - Jigs:

- Drill jigs, machining jigs, laminating jigs,made mainly to customer specifications

In-house design, construction and manufacturing

Precision Industry

Market segments:

- Aviation & Aerospace

- Medical & Optical

- Army & Defence

- Petrochemical Turbines

- General Engineering

- Automotive Industry

Products:

- Prototypes

- Single parts up to small series

- 5-axis simultaneous milling

- Length up to 2000 mm

- High-quality machining, from aluminium to titanium

In-house modelling and 3D programming (Co-design)

Engineering

For design and construction we use Cimatron, an integrated CAD/CAM system.

Participation during design, manufacture and consultation with the customer are essential to achieve the ultimate solution.

Tracing and functionality (Value-Analysis/ Value-Engineering) are top priorities.

Services

Due to our wealth of experience and in-house expertise at Breumaf, we have an excellent problem-solving capacity.

Intensive involvement throughout the manufacturing process enables us to guarantee optimum and reliable post-project assistance.

QA:ISO 9001/2000 and AQAP 2110 since 1994

Machinery

- Deckel Maho DMU-50 eVolution

5-axis simultaneous milling, with zero point system - Erowa ERS 206, with 45 pallets

Robot system with optional extensions - Deckel Maho DMU-60P

5-sided simultaneous milling - Deckel Maho DMC-65V

3-axis milling, highly accurate portal mill - Chiron FZ18L High Speed

4-axis milling up to 2000 mm - Charmilles

Erosion, wire and zinc sparking - Jung

Surface grinding - Schaublin

Conventional lathes - Deckel FP1, FP2, FP3, FP4

CNC and Conventional milling

Coordinates of drilling machines - Mitutoyo Crysta Apex C776

3D measuring from 3D model, (Soll-Ist value)

Robot made products

Robot executed with the most extensive self controlling software, to secure a reliable production process

Last update by Bob Breukers, Mon 2 Oct 2006